History:

On the ground floor, next door to the former Plating Shop, is the Stamp Shop. This still survives, with much of the original equipment intact and working, and forms one of the highlights of a visit to the museum. Along with casting, stamping was one of the two basic processes by which items of coffin furniture were made in the factory. Stamped products could be mass produced in great numbers, and were much cheaper to make than cast products.

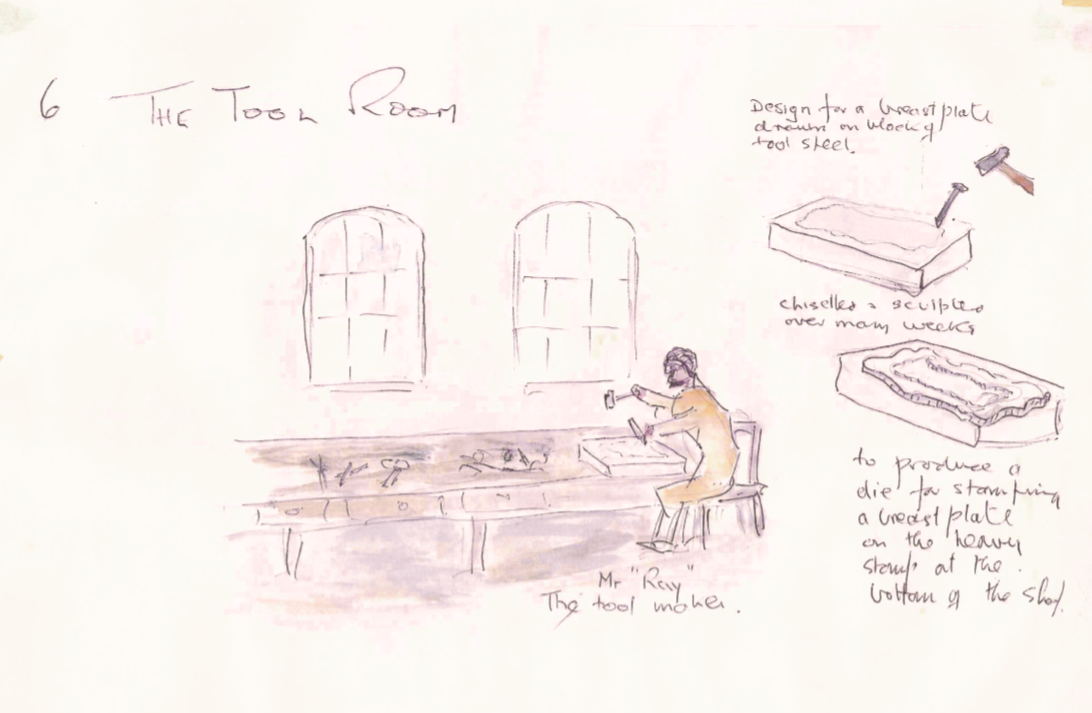

The basic piece of machinery is called a ‘drop stamp’. The process involves stamping a shape into a sheet of metal by dropping a heavy metal weight or hammer. In the Stamp Shop at Newman Brothers, there is a ‘battery’ of four drop stamps, from small to large, together with one very large drop stamp on its own. These are used to make coffin fittings in a range of sizes. The smallest drop stamp is suitable for making ornaments the size of a coin, while the biggest drop stamp was used to produce the breastplates that go on the lid of a coffin, engraved with the name of the deceased.